ExtrusionMaster

EH Wright Co teamed with Pinnacle Automation, Inc. and Rockwell Automation in 2012 to provide the most technologically sound and globally supportable control system in the industry for the extrusion process.

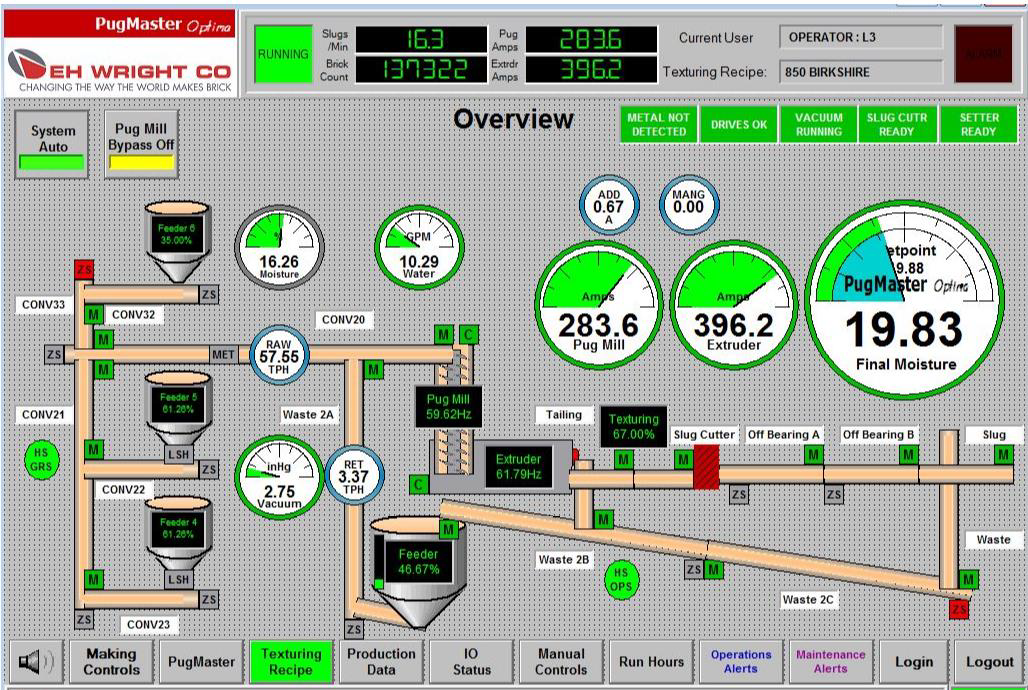

Utilizing Rockwell Automation’s FactoryTalk View SE platform, our engineering staff has designed the ExtrusionMaster to provide the plant Mill-Room with a Main Control Station featuring a single 15” Graphical HMI and one (1) button production start sequence.

The Making Controls screen is designed to display the specific material flow of the plant with Sequence Indicators and other Data Indicators as specified by the plant.

The Operator Control Station is supported by a Remote Main Control Component Enclosure, Remote I/O Moisture Transmitter HMI Enclosure and optional Remote I/O Enclosures to meet the plant requirements.

By incorporating the latest advancements in hardware and software technology, our industry leading design and programming staff have positioned the ExtrusionMaster to provide Mill-Room automation to meet the current and future needs of our industry.

BENEFITS

- Complete Mill-Room Automation Control

- Single Operator Control Point

- One Button Startup Sequence

- Integrated Architecture Provides Simplicity of Operation, Configuration and Maintenance

- “Laptop Free” Maintenance Support

- Column Control via PugMaster Optima

FEATURES

- Allen-Bradley GuardLogix Safety Controller with Safety I/O

- Allen Bradley Powerflex 527 Drives with Automatic Device Configuration

- Allen-Bradley Managed Ethernet Switch with DHCP Port Persistence

- PugMaster Optima – Embedded

- Texturing Recipe Management

- I/O Status with Manual Control

- Operator/Maintenance Alerts

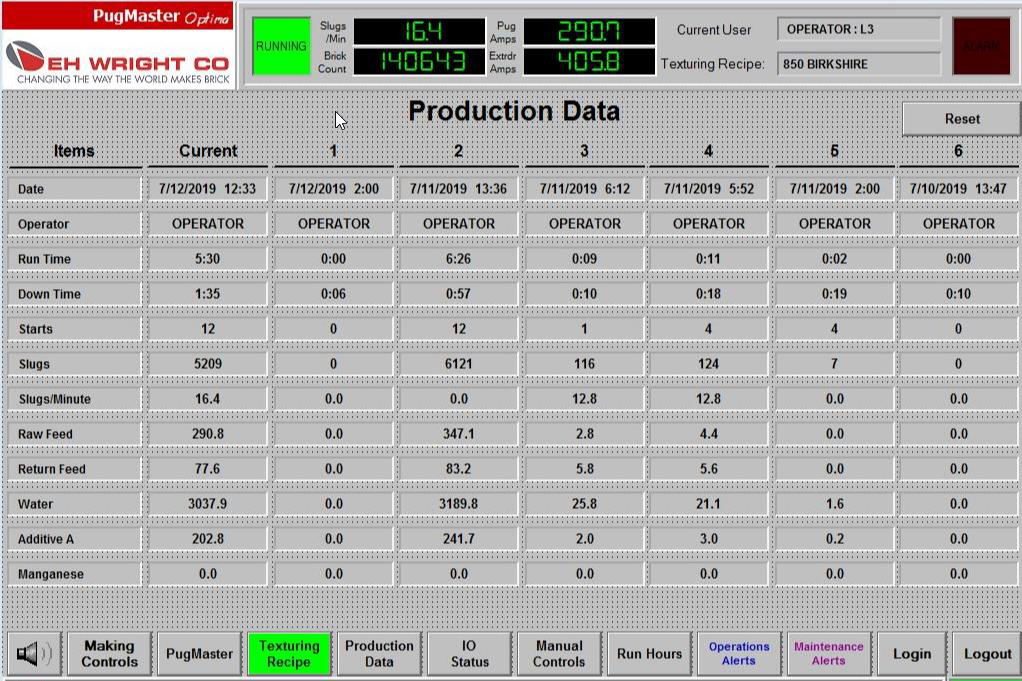

Production Data

Seven Day Production Data Report.

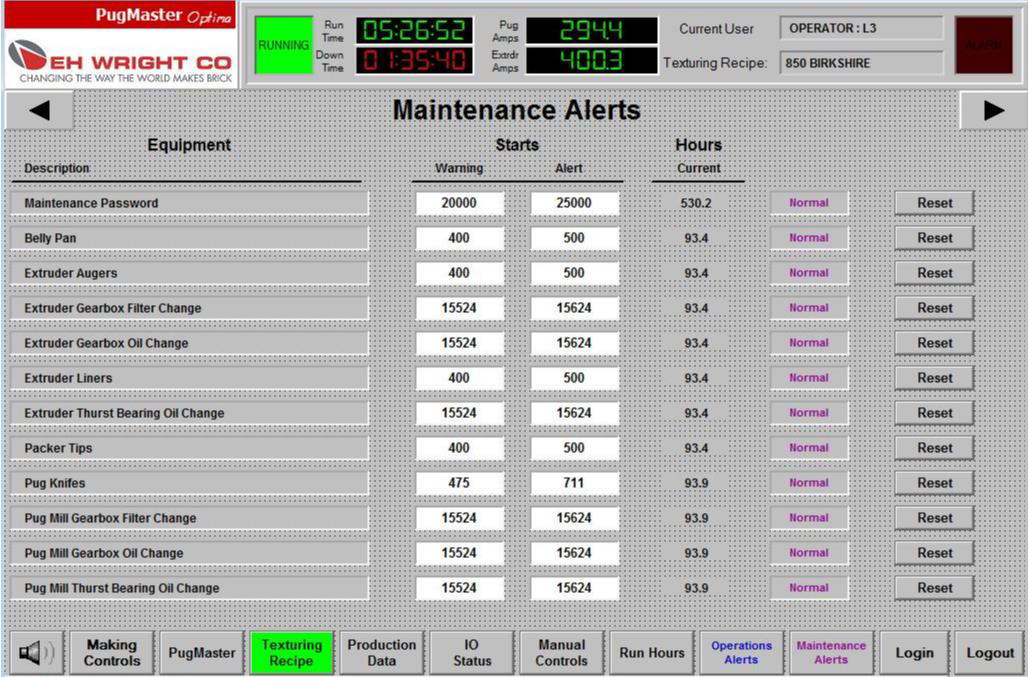

Maintenance Alerts

Schedule Machine Maintenance Based Upon Hours In Service –HMI Configurable.