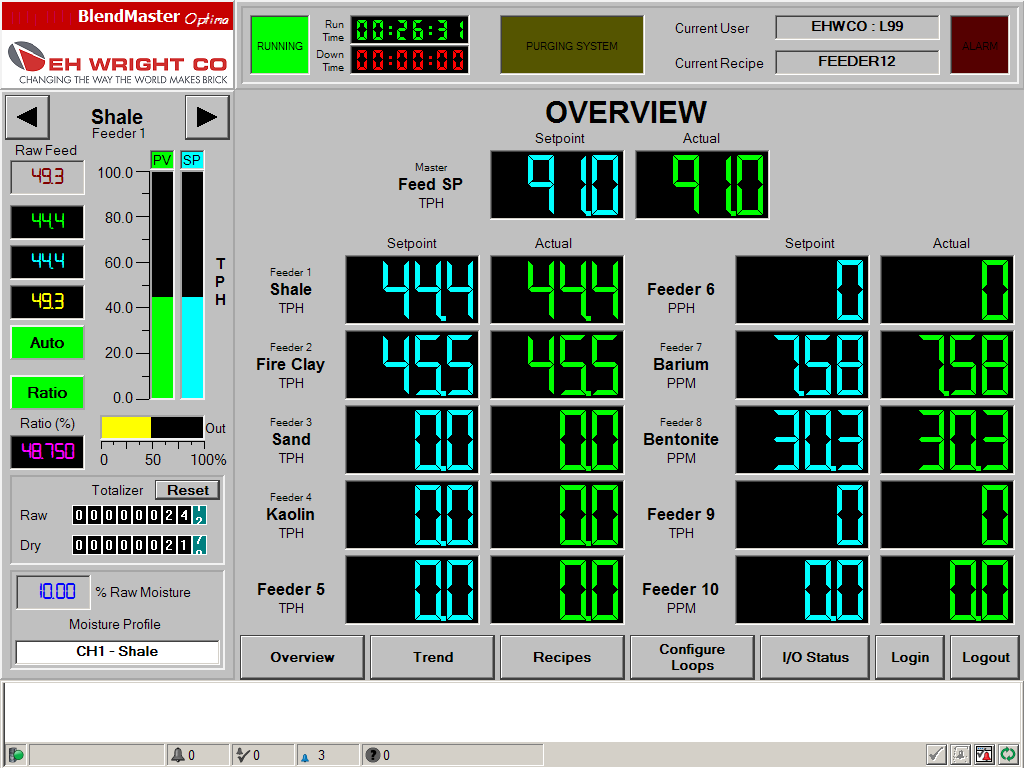

BlendMaster Optima

A continuous, moisture compensated, blending controller for precise blending of the body material prior to the extrusion process. It too is based on the same Rockwell Automation technology as the PugMaster Optima with the same look and feel.

The BlendMaster Optima is capable of controlling ten (10) moisture compensated or non-compensated feeders. The feeders are electronically positioned on the belt so that the correct amount of material is dispensed at the right place and at the right time. This eliminates any out of spec material on startups, shutdowns and master setpoint changes. Another unique feature of the BlendMaster Optima is an Output Deviation Alarm. This alarm will provide an early warning of a failing loadcell or a blocked or bridged feeder.

BENEFITS

- Accurate and Repeatable Blends

- Continuous Monitoring of the Blending System

- Repeatable Batches

FEATURES

- Total Feed Rate Control

- Moisture Compensated Feed Rates

- Ten (10) Feeder Controls

- Output Deviation Alarms

- Trending (Real-Time & Historical)

- Recipe Management

- User Management w/Auto Logout

- Remote Control via Ethernet

- Remote Diagnostics via Ethernet Modem or VPN

- Universal Analog Inputs and Outputs

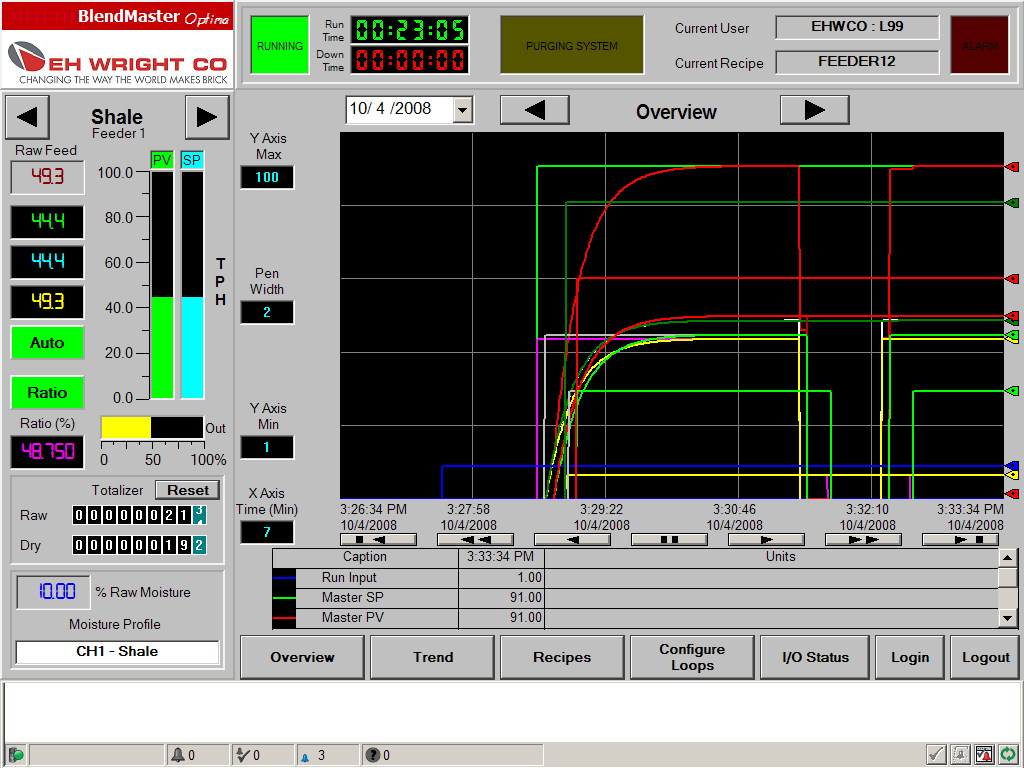

Historial Trending

With Historical Trending you are able to easily and accurately view and evaluate the performance of your material blending system.

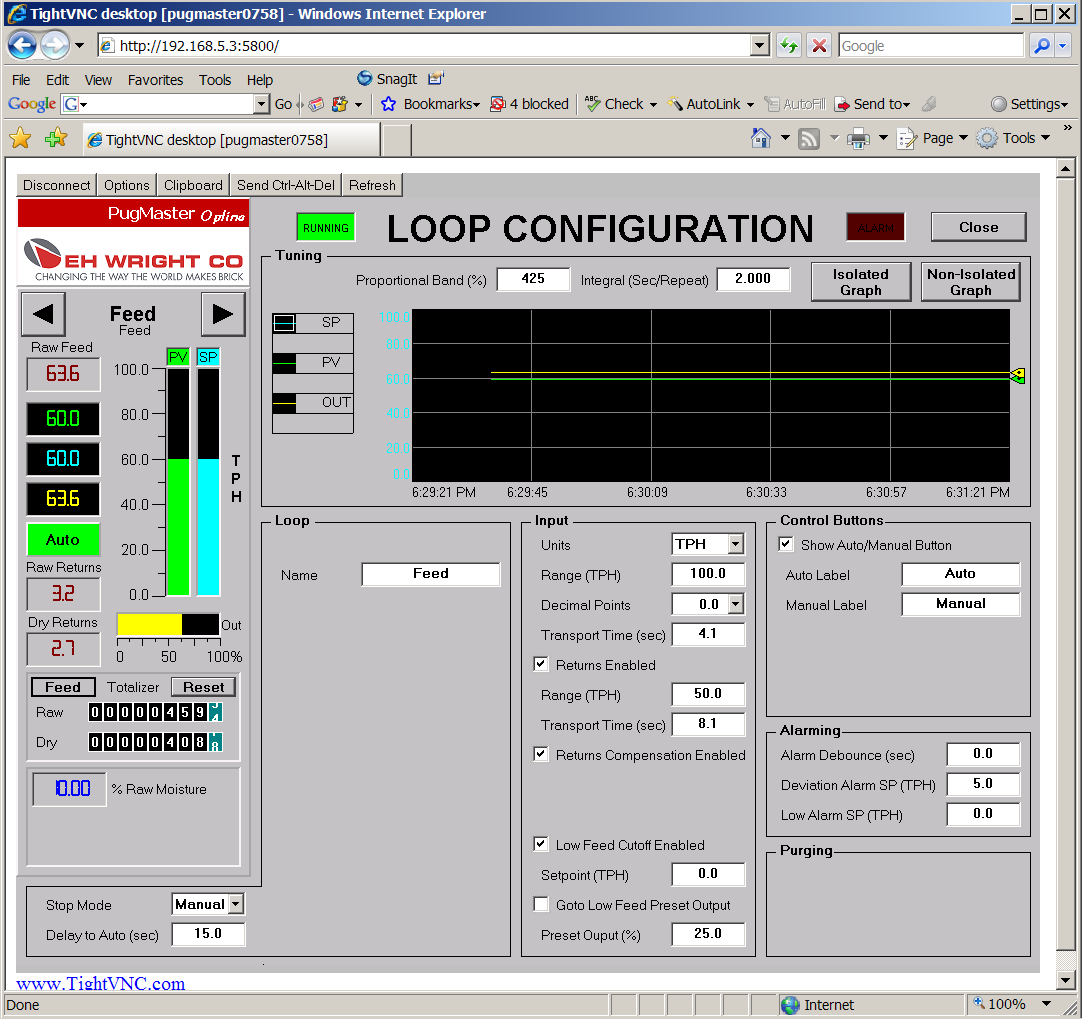

Remote Diagnostics

With Remote Diagnostics, EH Wright Co’s qualified staff is standing by to assist you when problems arise. Whether it is a simple system configuration issue or a process problem, we are here to help.